So every person who decides they want to make a bike from wood will inevitably be asked, at almost every turn, “Why wood?”, and to be fair, it’s not an obvious material choice for building a bike. However, the first airplanes were made of wood, and there are wooden structures standing today that were built over a thousand years ago.

Perhaps a better question to ask is what properties make a material good for building a bike? There are three main characteristics of a bike frame that will be directly influenced by the material choice and thus properties: weight, strength, and stiffness. The characteristics of the bike frame, not the materials from which it is built, are ultimately what determines the quality of the ride. In general terms, the bike builder wants to minimize weight while maximizing strength and stiffness, however, an increase in strength and stiffness generally corresponds to an increase in weight. So a balance must be struck, and for the last 100 years or so, the design of the bike frame has remained mostly unchanged as this balance has largely been found.

How does this relate to wood as a bike material? Glad you asked. The frame characteristics are the ultimate goal, which means the the material properties are important but secondarily so. There is a lot of freedom in design if the end goal is only to satisfy a strength, weight, and stiffness criterion. Because wood is much less dense than either aluminum or steel (we are going to ignore carbon for the purposes of this discussion) a much larger tube diameter can be considered. This is fortunate because, while wood is much less dense, it is also much weaker and much less stiff than either aluminum or steel.

Remember though, that the frame characteristics are what matter. So, by using a larger diameter for the cross section of the tube than for metal, we increase the area moment of inertia (henceforth called “I”) and thus increase the section stiffness of the tube. The actual stiffness of the tube is a function of both the material’s modulus of elasticity (E) and I. So, wood has a lower E but can achieve a higher I for the same weight as a comparable aluminum or steel tube.

Similar analysis can be made for the strength of the tube. At some point I will write a bit more about it here.

Alright, that’s a bit of a wall of text but the short of it is this: by increasing the diameter and wall thickness of the wood tube, we can match the weight, stiffness, and strength of an aluminum or steel tube. So what diameter does the tube need to be? Well, it depends on the wood, and which tube (top tube, down tube, seat tube), and what type of bike (mtb, road, track, etc.).

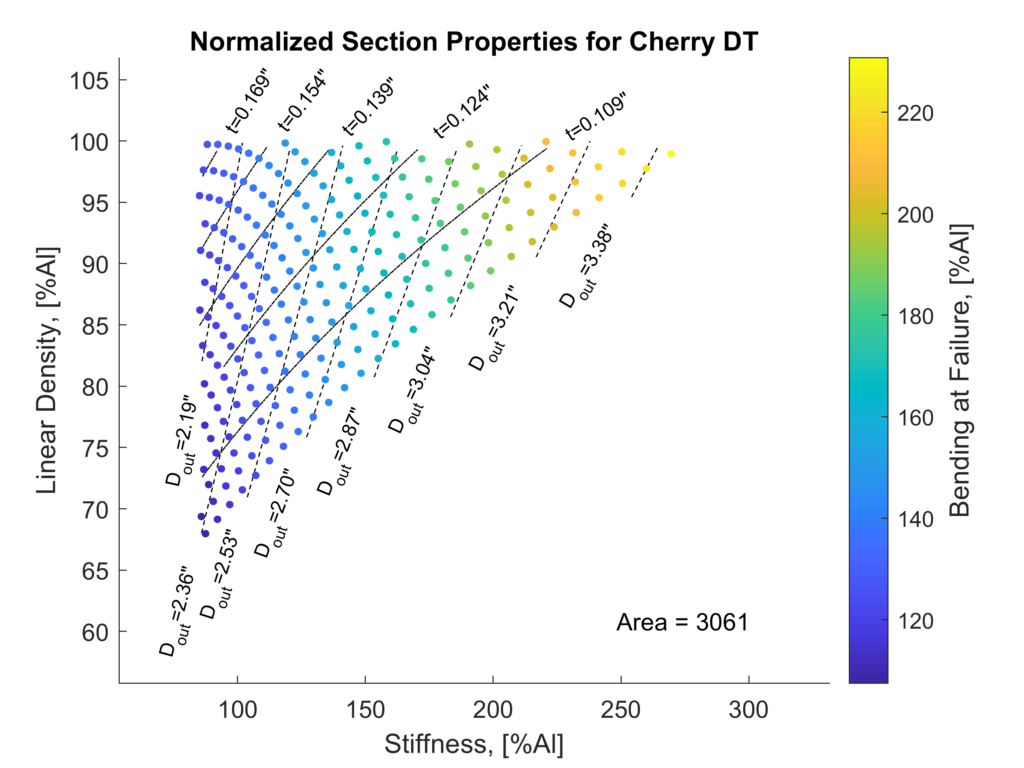

I wrote a matlab script to help me understand the interplay of these variables: wood species (read: material properties), tube diameter, tube wall thickness, weight, stiffness, and strength. Initially, I used the script to choose what type of wood to build the next bike from. (Turns out that the woods I used on the last bike are a bit on the dense side.) I settled on cherry for a couple of reasons which I will talk about more in the post about the hardtail as I update it. After that, I used the script to determine the range of wall thickness and tube diameters that would give me properties that matched or exceeded those of the 7005 aluminum tubeset from nova cycles.

Because there are effectively five variables at play and I wanted to visualize all the information on one plot, I had to spend a lot of time thinking about how to format the graph. The plot shows the three tube properties as percentages of the aluminum counterpart and shows lines of constant outer diameter and tube thickness.

Fascinating! I always wondered how wooden bikes could stand against metal ones. Beautiful woodwork! Can’t wait to see how Mk. 2 turns out.